VFGSH-2400/2800/3200A/C High Speed Double Servo Control Folding Gluing and Stitching Machine

Carton sizes are directly input HMI. When input parameters in HMI ,click auto adjustable button, the left & right, front & rear of each unit are automatically adjusted and positioned, also can click button to fine tuning, Cardboard

VZXA-S2400/2600/2800A Automatic Computer Controlled Folding Gluin

- Technical Parameter

- Product Details

- Video Online Message

-

- Commodity name: VFGSH-2400/2800/3200A/C High Speed Double Servo Control Folding Gluing and Stitching Machine

Carton sizes are directly input HMI. When input parameters in HMI ,click auto adjustable button, the left & right, front & rear of each unit are automatically adjusted and positioned, also can click button to fine tuning, Cardboard

● Main Specifications:

Model

VFGSH-2400

VFGSH-2800

VFGSH-3200

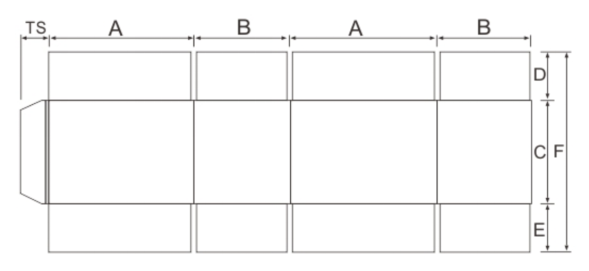

Max. Sheet Size(A+B)×2

2400mm

2800mm

3200mm

Min. Sheet Size(A+B)×2

750mm

750mm

750mm

Max. Box Length (A)

700mm

800mm

1000mm

Min. Box Length (A)

200mm

200mm

200mm

Max. Box Width (B)

500mm

600mm

600mm

Min. Box Width (B)

175mm

175mm

175mm

Min. Sheet Height (D+C+E) F

295mm

295mm

295mm

Max. Sheet Height (D+C+E) F

1000mm

1000mm

1000mm

Min. Stopper Measurement(D)

0mm

0mm

0mm

Max. TS Width (TS)

30-40mm

30-40mm

30-40mm

Cardboard Thickness

3-9mm

3-9mm

3-9mm

Gluing Speed

100M/minute

100M/minute

100M/minute

Stitching Speed

1000nails/minute

1000nails/minute

1000nails/minute

Stitching Pitch

30-90mm(Tie nail 30-70mm)

30-90mm(Tie nail 30-70mm)

30-90mm(Tie nail 30-70mm)

No. of Stitching

1-99 Stitches or more

1-99 Stitches or more

1-99 Stitches or more

Power Required

72HP(54KW)

72HP(54KW)

72HP(54KW)

Input Voltage

380V three phase

380V three phase

380V three phase

Stitching Wire

(0.65-0.75)* (1.8-2.0)mm

(0.65-0.75)* (1.8-2.0)mm

(0.65-0.75)* (1.8-2.0)mm

Stitching Wire Tray

20KG

20KG

20KG

Machine Length

21000mm

21000mm

21000mm

Machine Width

4200mm

4600mm

5500mm

Machine Weight

17T

18T

20T

-

● Applications and Characters:

1.Electric Control and Operation:

- Carton sizes are directly input HMI.

- When input parameters in HMI ,click auto adjustable button, the left & right, front & rear of each unit are automatically adjusted and positioned, also can click button to fine tuning, Cardboard thickness(upper and lower) is adjusted by motor.

- Easy to save parameter setting by orders, then read each order serial to shift order, then is auto adjusted.

- Can be memorized after fine tuning, keep high performance parameter setting.

- Saving orders serial more than 10000+.

2. Feeding Unit

- Lead edge feeding: red glue on the back of the timing belt. Each belt can be synchronously or adjusted separately belt height to compensate belt wear.

- Feeding suction negative pressure: on the left and right belts and VR operation to ensure the stability of the cardboard conveying. The upper and lower belt gaps can be adjusted manually. Inverter control, VR operation.

- To ensure cardboard is feeding in parallel, each belt suction can be manually adjusted on or off.

- Extended cardboard feeding function: friction coefficient is lowor or long cardboard can be out puted smoothly, its setting in touch screen.

- Cardboard feeding roller: rubber wheel (wear-resistant rubber), embossing wheel (chrome plated surface), axle body is stress relieving after welding to avoid deformation and bending; Static balance correction to avoid vibration during operation. Cardboard thickness gap(high and low) manually adjusted with scale line.

- The timing belt speed of lead edge feeding is synchronized feeding rubber pulley speed ; Even if the belt wear ,which speed can be synchronized rubber wheel, avoid timing belt speed and rubber wheel speed is different, then caused cardboard is deflective or rubber wheel is worn abnormally and rapidly.

- Front stopper: with hand shank to adjust different thickness of cardboard, with scale line.

- Side baffle: moving left and right automatically, positioning is automatically adjusted by order parameter setting, also with electric fine tuning and limit switch protection.

- The left baffle (operating side) is with air pressure side shoot function, 110mm length, and the side shoot frequency is freely set by HMI.

- Back stoppers:forward & backward moving positioning are automatically adjusted by order setting, also fine tuning with buttons,with limit switch protected.

- The main conveying motor of feeding unit is variable frequency stepless speed, VR operation.

3. Folding Unit

- Lower conveyor belt: Patterned belt is perforated and with air suction cardboard feeding device. belt is welded by hot melting without steel buckle. It is unnecessary to disassemble any structure when replacing the belt.

- Up folding belt: the left and right sides of the patterned belt are driven independently, and speed is adjusted independently by frequency controlled. VR operation, compensate folding resistance.

- Folding roller: limit the folding position of cardboard, so cardboard can be formed more accurately.

- Folding side pulley: keep folding cardboard in 180°.

- The angle of the bending pole is fixed with upper folding belt, easy operating, only adjust folding pole upper or down position for big size cardboard.

- Left and right folding are automatically adjusted by order setting, also fine tuning with buttons,with limit switch protected

4. Others:

- Left and right belts, squaring push plate, forward and backward moving positioning are automatically adjusted by order setting, also fine tuning with buttons, with limit switch protected.

- Squaring section used servo motor, speed fast, accurate, no fish tails.

- Belt gap was electrical adjusted, with scale line.

- Cardboard jam will be automatic stopped, which controlled by Photoelectric.

- Correction with first cardboard, squaring section can be manually operated fr micromotion, keep squaring more accurately.

5. Stitching Unit:

- Stitching speed:1000nails/minute.

- Stitching wire Width*Thickness (1.8-2.0mm) * (0.65-0.75mm).

- Big wire automatic feeder (20KG).

- Nail length 38mm.

- Nail type: single / / / /; double nail // // // //, tie nail: // / / //; nail distance :30-90mm.

- Nail angle direction: 45゚.

- Joint flap width (TS) 30-40mm.

- Stitching head used servo control system.

- Cardboard feeding used servo control system.

- It is electrical adjust for the belt of stitching section, with limit switch protected.

- Electrical adjustable for die counter gap, it is adjusted by cardboard thickness, with scale line.

- Conveying belt gap is easy to adjust, keep the light pressure mark rule to adjust gap, and with scale line.

6. Gluing Unit:

- Gluing speed 100m/min.

- Easy to adjust gluing value.

7. Gluing Unit:

- Auto counting, it can be stack 10-20pcs for 3layer, 5-10pcs for 5layer.

- Gradually stack to avoid cardboard box topple and fall.

- Push back structure, keep cardboard box stack is orderly when it is conveying.

- Servo motor control for back push rod

-

Online Message

Related Products