DCP-A4-20/30/35/40 Copy Paper Automatic Cutting and Ream Wrapping Machine

RS-S1400/1700/1900 High Speed Servo Precision Single Rotary Blade Paper Sheeter

DCP-A4-20/30/35/40 Copy Paper Automatic Cutting and Ream Wrapping

- Technical Parameter

- Product Details

- Video Online Message

-

- Commodity name: DCP-A4-20/30/35/40 Copy Paper Automatic Cutting and Ream Wrapping Machine

RS-S1400/1700/1900 High Speed Servo Precision Single Rotary Blade Paper Sheeter

● Main Specifications:

Model

DCP-A4-20

DCP-A4-30

DCP-A4-35

DCP-A4-40

☞ Sheeting Machine:

Unwinding Paper Reels

4

5

5

5

Number of Pocket

4

4

5

6

Max. Width of Paper Roll

846 mm

846 mm

1056 mm

1266 mm

Net Cutting Width

840 mm

840 mm

1050 mm

1260 mm

Diameter of Paper Roll

400-1200

Diameter of Core Chuck

3” (76.2mm) or 6” (152.4mm)

Paper Weight

60-100gsm

Length of Sheeted Paper

297 mm

Paper Quantity Per Ream

0-500pcs

Max. Ream Height

65 mm

Max. Design Speed

300m/min

Working Speed of Paper Feeding

180~220m/min

200~260 m/min

200~260 m/min

200~260 m/min

Working Cutting Speed

437 times/min

650 times/min

650 times/min

780times/min

Ream Discharging Speed

16~20 reams/min

25~30 reams/min

28~35 reams/min

35~40 reams/min

Max. Knife Loading

400gsm (4×100)

Paper Cutting Accuracy

±0.2mm

Requirement for Paper Reel

1. Stable Speed

2. Paper roll with no breakage

3. Qualified paper.

Transmission

AC Frequency conversion, stepless speed regulating

Main Power Source

380v/50Hz 3phase 4 wires

Control Voltage

220V AC/22V DC

Total Power

28.5kw

29.5kw

35kw

40kw

Overall Dimension

16.5×2.75×2.1m

18.5×2.75×2.1m

20×2.96×2.1m

20×2.96×2.1m

Weight

22T

25T

27T

32T

Wrapping Machine:

Production Speed

20~25 reams/min

25~30 reams/min

28~35 reams/min

35~40 reams/min

Motor Power

6.5kw

Gluing Power

2.75kw

2.75kw

2.75kw

2.75kw

Compressed Air

0.6~0.8MPa

Overwrapping Paper Size

550-560×386mm

Overall Dimension

4.53×3.05×1.5m

4.53×3.05×1.5m

4.53×3.05×1.5m

4.53×3.05×1.5m

Weight

2T

2T

2T

2T

-

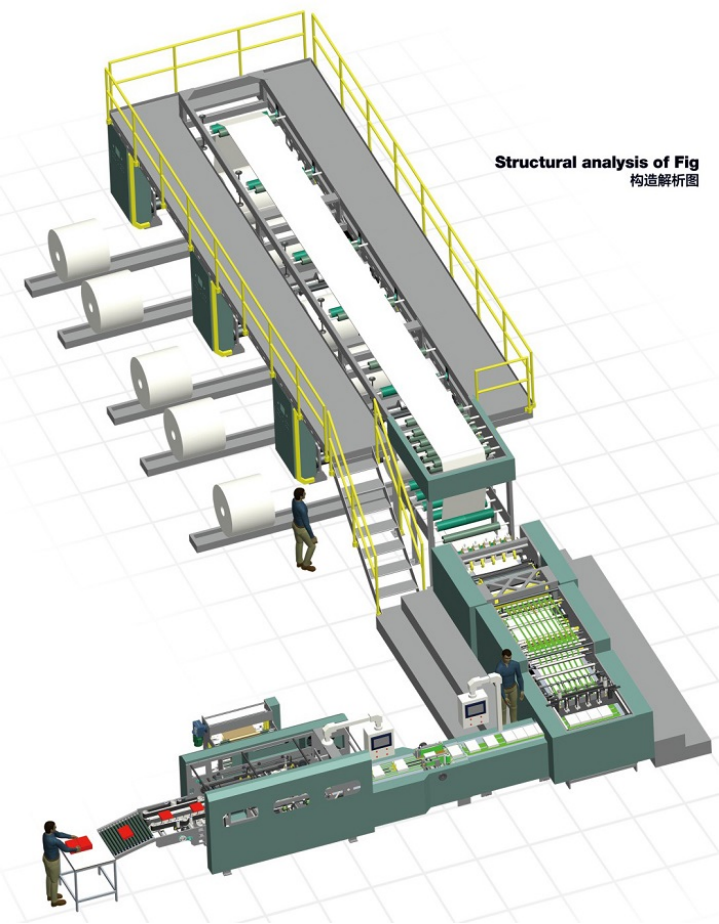

● Applications and Characters:

Fully Automatic A4 Copy Paper Cut Size Sheeting 8 Wrapping Machine (DCP-A4-20/30/35/40) is the bestchoice for the A4 copy paper production.

- Function: cutting & ream wrapping

- Cut size: A4 (210mm*297mm)

- Ream output speed:35—38 reams/min 5 rolls 5 pockets

- Max. speed: 220m/min

- Capacity: Approx. 10000reams/shift (8 hours)

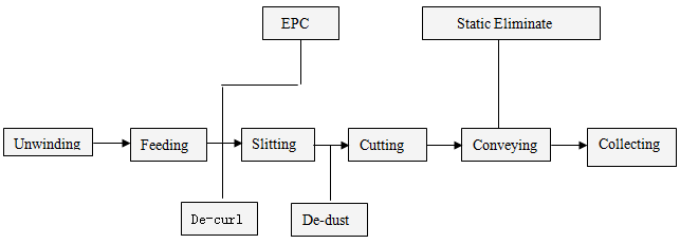

As technics of our machine, we hereby describe the related functions and work flow for paper products: unwinding→ cutting → conveying → collecting → Packaging.

❈ Partial Introduction:

1. Unwind Stand (3Sets = 5 Rolls)

- Machine Type: Each machine table can take 2 sets of shaftless paper rack. (Include 3 sets of railway and trolley)

- Diameter of the Paper Roll: Max. Ф1500mm

- Width of the Paper Roller: Max. 1200mm

- Paper Rack’s Material: Steel

- Clutch Device: Multi Pneumatic Breaker and Automatic Tension Control

- Clip Arm’s Adjustment: Manual adjust by oil pressure

- Paper Core Demanding: 3” (76.2mm) or 6” (152.4mm) or according to the client’s need

2. Unwind Stand (3Sets = 5 Rolls)

When the paper through inductor, that automatic feedback to the PLC control system to increase brake load, increaseor reduce the tension that control the paper tension automatically

3. High Precision Cutting Knife System:

- Upper and lower knives are rotary make the cutting accuracy is highly precision.

- Anti-curve device include one set of square bar and steel wheel. When the curve paper through paper edge unit that can adjust the paper square and let it flat.

- 5 Sets Slitting Knives: Upper slitting knife take by air pressure and spring. Lower knife connect with bear drive (The diameter is Ф200mm) and move with spring. The upper and lower round knife is made by SKH. The lower slitting knife (Diameter is Ф200mm) and drive with in-phase belts. The lower slitting knife is 5 groups, each group have 2 knife edges.

4. Paper Feeding Wheel:

- Upper Wheel: Ф200×900mm (Rubber Covered)

- Lower Wheel: Ф400×1000mm (Anti-glide)

5. Cutting Knife Group:

- Upper Cutting Knife: 2 Sets 1100mm

- Lower Cutting Knife: 2 Sets 1100mm

6. Driving Group (High precision bear and belt drive)

7.Main Driving Motor Group: 30kw

❈ Ream Wrapping Machine:

- Conveyor System for Reams Placement (800×1100) 1 Set

- Ream Accelerated to Placing System: 1 Set

- Unwind Stand for Packing Roll: 1 Set

- Lifting System for Reams: 1 Set

- Pressing and Tighten System for Reams: 1 Set

- Lower Folding System for Packing Sheets: 2 Sets

- Angle Overlapping System for Packing Sheets: 1 Set

- Steadfastness Angle Overlapping for Packing Sheets: 1 Set

- Spraying Hot Melt Glue System for Packing Sheets: 1 Set

- PLC System for Alarming, Auto Stop of Break-Down: 1 Set

- PLC Controlling System: 1 Set

-

1111111

Online Message

Related Products