FFG-HL2000/2400/2800 Full Computerized Controlled Flexo Printing Slotting Die Cutting Inline Folder Gluer Machine

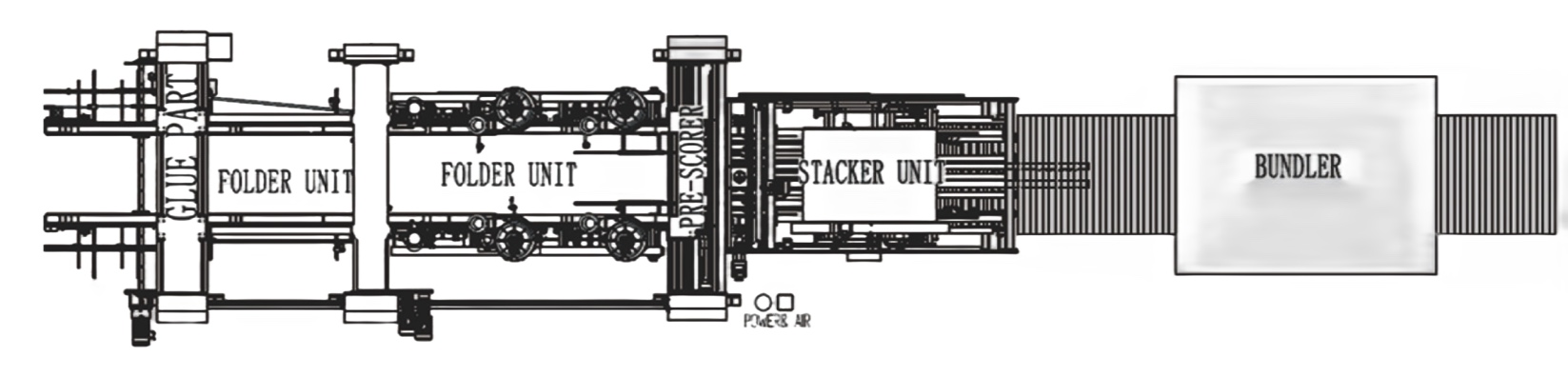

FFG-HL Full Computerized Flexo Printing Slotting Die Cutting Inline Folder Gluer Machine can be equipped with VPSH-S or VPSH-D series Flexo Printer, and equipped with the auto pre-feeder, automatic strapping machine, mechanical arm and realized feeding, printing, slotting, die cutting, box folding gluing and automatic packaging integrated production.

Flexo Folder Gluer

Case Maker

Box Maker

Flexo Printing Slotting Die Cutting Machine

Flexo Printer Slotter Die Cutter Machine

- Technical Parameter

- Product Details

- Video Online Message

-

- Commodity name: FFG-HL2000/2400/2800 Full Computerized Controlled Flexo Printing Slotting Die Cutting Inline Folder Gluer Machine

- Commodity ID: 01

FFG-HL Full Computerized Flexo Printing Slotting Die Cutting Inline Folder Gluer Machine can be equipped with VPSH-S or VPSH-D series Flexo Printer, and equipped with the auto pre-feeder, automatic strapping machine, mechanical arm and realized feeding, printing, slotting, die cutting, box folding gluing and automatic packaging integrated production.

● Main Specifications:

☞ Full Computerized Controlled Flexo Printing Slotting Die Cutting Machine (Top Printing with Vacuum Transfer):

Model

VPSH-S/D0920

VPSH-S/D0924

VPSH-S/D1224

VPSH-S/D1228

Max. Speed

300pcs/min

300pcs/min

280pcs/min

280pcs/min

Max. Paperboard Size

880×2000mm

880×2400mm

1180×2400mm

1180×2800mm

Min. Paperboard Size

300×650mm

300×650mm

350×750mm

350×750mm

Skip Feeding Size

1100×2000mm

1100×2400mm

1500×2400mm

1500×2800mm

Max. Printing Size

800×2000mm

800×2400mm

1200×2400mm

1200×2800mm

Thickness of Printing Plate

7.2mm

7.2mm

7.2mm

7.2mm

Min. Slotting Space

240×80×240×80mm

240×80×240×80mm

240×80×240×80mm

240×80×240×80mm

Max. Slotting Depth

250mm

250mm

320mm

320mm

Max. Paperboard Thickness

12mm

12mm

12mm

12mm

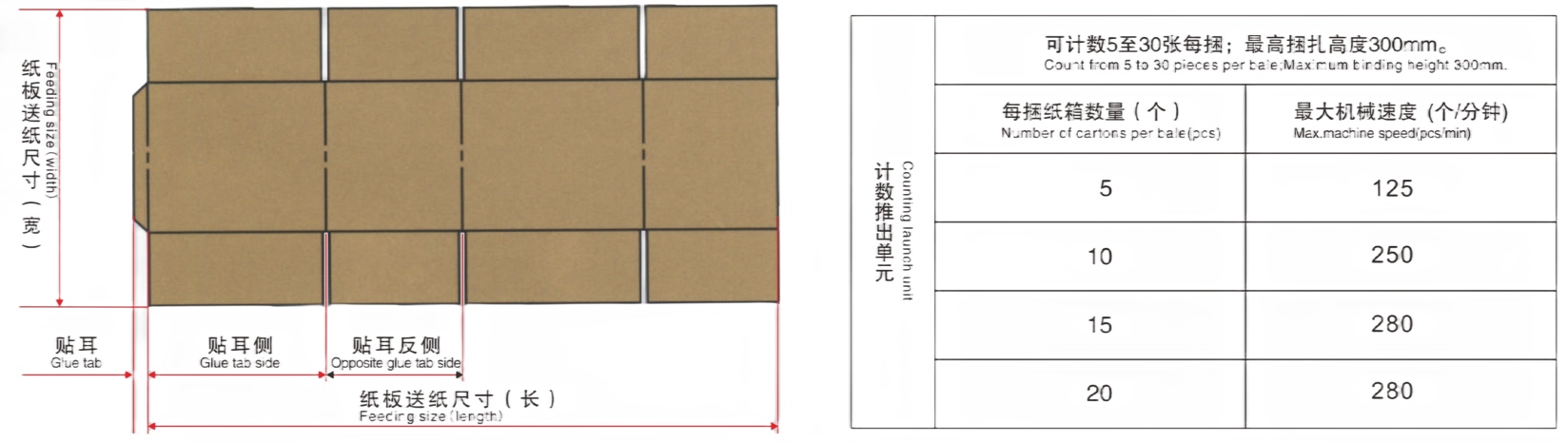

☞ Full Computerized Controlled Downward Fold Inline Box Pasting Machine:

Model

FFG-HL2000

FFG-HL2400

FFG-HL2800

Max. Speed

280pcs/min

320 pcs/min

320 pcs/min

260 pcs/min

Max. Paperboard Size

880×2000mm

880×2400mm

1180×2400mm

1180×2800mm

Min. Paperboard Size

300×650mm

300×650mm

350×750mm

350×750mm

Max. Printing Size (No Ratifications)

800×1960mm

800×2360mm

1180×2360mm

1180×2760mm

Max. Printing Size (With Ratifications)

800×1900mm

800×2300mm

1180×2300mm

1180×2700mm

Max. Panel Size

Glue Tab Side

810mm

1010mm

1010mm

1100mm

Opposite Glue Tab Side

810mm

1010mm

1010mm

1100mm

Min. Slotting Space

Glue Tab Side

130mm

130mm

130mm

130mm

Opposite Glue Tab Side

130mm

130mm

130mm

130mm

Glue Tab Width

<45mm

<45mm

<45mm

<45mm

-

● Applications and Characters:

FFG-HL Full Computerized Flexo Printing Slotting Die Cutting Inline Folder Gluer Machine can be equipped with VPSH-S or VPSH-D series Flexo Printer, and equipped with the auto pre-feeder, automatic strapping machine, mechanical arm and realized feeding, printing, slotting, die cutting, box folding gluing and automatic packaging integrated production.

☞ VPSH-S/D0920/0924/1224/1228 Full Computerized Controlled Flexo Printing Slotting Die Cutting Machine (Top Printing with Vacuum Transfer):

Europe and the United States design concept; mobile unit; the whole vacuum adsorption printing; can be equipped with hot air, infrared, UV, independent drying device and doctor blade to achieve full-screen printing; independent computer touch screen PLC control; can store commonly used orders; rapid version changing function; fast ink wash and ink-saving function; oil automatic balancing device; die cutting frequency compensation device; optional remote maintenance; rapid equipment trouble shooting.

1. Feeding Unit:

Sun Automation Lead Edge Feeder with strong vacuum transfer for precise and stable feeding.

Dust removal system with brush and segmented vacuum sheet cleaner.

Self-locked system adopted for adjusting feeding rolls gap. Motorized and PLC control of feeder side guides.

Main motor is protected from starting up when units are not fully closed and locked.

2. Printing Unit with Vacuum Transferring:

Pneumatic clutch is adopted on the anilox roll to: (a) make the roll run at the same speed as the main motor when the unit is printing; (b) make the roll stop when the unit is not printing; (c) reduce the possibility of damage to the rubber roll and the anilox roll for improper operation; (d) allow units which are not in use to be washed up while running.

Transverse register is also digitally controlled by motor and PLC (±10mm).

Cleaning Function can be automatically switched to ensure the ink recycling thoroughly.

Automatic resetting after cleaning the printer.

Doctor-Blade Inking System (Optional).

3. Slotting Unit:

An internal gear adjusts the height of the carton box and prevents the lubricating oil from spilling or leaking on to the paperboard

Upper boss and lower boss are coupled to keep the two knives aligned while moving, which is helpful to prolong service life.

Slotting register and height of carton box are digitally controlled by motor and PLC.

Motorized controls of the slotting bosses caliber.

A protective device prevents the slotting knife from crashing when the height of the carton box is adjusted.

4. Die Cutting Unit:

Side to side oscillation of anvil drum (50mm).

The die cut cylinder lateral register is digitally controlled by moto and PLC, rang about ±10mm.

Anvil rubber roller speed compensation adopted independent motor for driving to control the rubber roller speed, the compensation scope is ±3mm.

Anvil trimmer to keep surface of the anvil covers flat and smooth.

☞ VDFGH-0920/1224/1628T High Speed Automatic Down Folding Gluing Machine:

1. Folding Unit:

- Through glue spraying system follow spraying automatic, no need contact with cardboard surface.

- Spraying system can depend on customer demands, option VLACO, HHS, KQ.

2. Gluing Unit:

- High rigidity beam, precise lateral moving system.

- Accurate linkage system with printing department.

- Computer control automatically sets the fuselage position.

- Adopt Swiss HABAXI imported conveyor belt, ensure feeding register vacuum transportation when folding.

- The tension of the conveyor belt can be adjusted separately.

- Conveyor pressure is adjustable.

- The Folding Bar system is adopted to make the folding more smooth and smooth.

- Automatic waste removal device, effectively remove nail paste edge paper.

- 1) Through glue spraying system follow spraying automatic, no need contact with cardboard surface.

- 2) Spraying system can depend on customer demands, option VLACO, HHS, KQ.

- 3) The computer control automatically sets the position of the spray device, which can set three or four lines of glue.

- 4) The spray head can be upside down to do Outside Glue Lap work.

3. Hopper and Correction Unit:

- Running unit combined with lead screw and linear guide rail.

- Computer control automatically sets the position.

- Strong blowing pressure device.

- Full shot calibration device.

- The side guide ensures more accurate calibration.

- Use sensors to control the stacking height of cardboard.

- Automatic emergencies stop when the cardboard discharge is not smooth.

- Micro-adjustment of discharge clearance.

- Suction conveyors discharge at high speed.

4. Counter Ejector:

- High accurate control stacker quantity.

- Set quantity of cardboard, push out by air cylinder board.

- The amount of output is automatically set by computer control.

- The counting discharge part of the upper stacking mode does not damage the quality of the printed surface.

- Suitable for high-speed production.

- Electric side-to-side movement.

- Press tightly with the press roller, the gap is electrically adjusted.

- Discharge conveyor system.

Online Message

Related Products