MHC-1060/1080AT Automatic Hot Foil Stamping & Die Cutting Machine (Heavy Duty)

MHC-1060/1080AT Automatic Hot Foil Stamping & Die Cutting Machine (Heavy Duty)

MHC-1060/1080AT Automatic Hot Foil Stamping & Die Cutting Machine

- Technical Parameter

- Product Details

- Video Online Message

-

- Commodity name: MHC-1060/1080AT Automatic Hot Foil Stamping & Die Cutting Machine (Heavy Duty)

MHC-1060/1080AT Automatic Hot Foil Stamping & Die Cutting Machine (Heavy Duty)

● Main Specifications:

Model

MHC-1060AT

MHC-1080AT

Max. Sheet Size

1060×760mm

1080×780mm

Min. Sheet Size

400×350mm

Max. Cutting Size

1050×750mm

1070×770mm

Max. Hot Stamping Size

1050×750mm

1070×770mm

Max. Embossing Area

1050×750mm

1070×770mm

Gripper Margin

9-17mm

Inner Chase Size

1100×790mm

Stock Range

Paper: From 90 to 2000g/m2, 0.1~2mm Paper, Corrugated Board: Up to 4mm

Die Cutting Accuracy

≤±0.1mm

Common Stamping Accuracy

≤±0.1mm

Hologram Positioning Stamping Accuracy

≤±0.1mm (Optional)

Embossing Accuracy

≤±0.1mm

Max. Die Cutting Force

600T

Max. Working Speed

7500s/h

Max. Feeder Pile Height

1600mm (With Wooden Pallet)

Max. Delivery Pile Height

1400mm (With Wooden Pallet)

Max. Gold Foil Diameter

250mm (Longitudinal), 200mm (Transversal)

Electric-heated System

20 temperature ranges, 40-180℃ is adjustable

Foil Width

20~1020mm

Main Motor Wattage

11kw

15kw

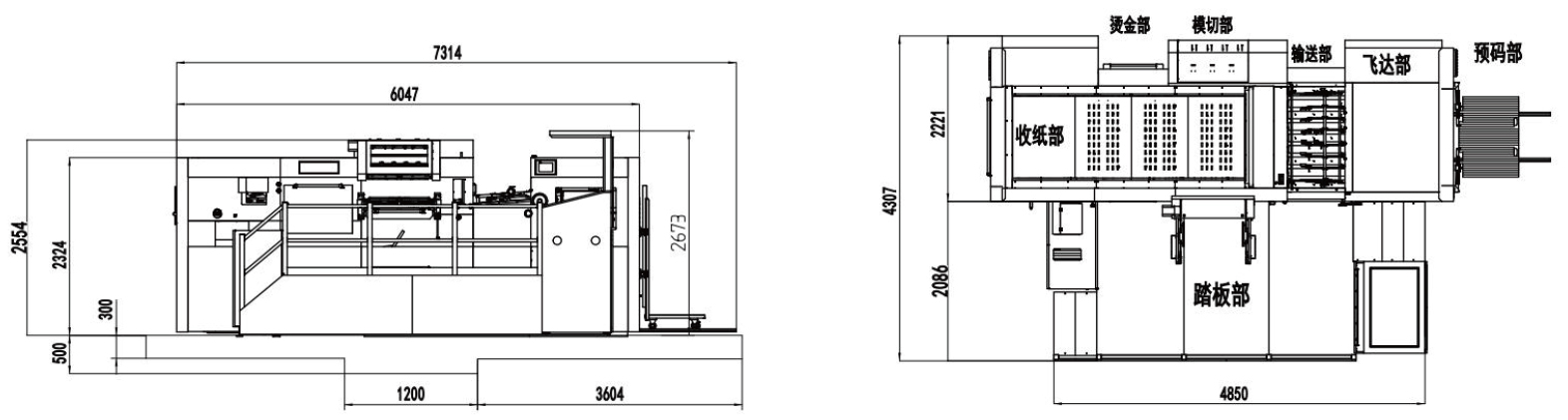

Overall Dimensions

7314×4307×2367mm (L×W×H)

(L: paper prepared track included; W: platform included)

Net Weight of Machine

20T

20.5T

Main Motor Wattage

15kw

15kw

Full Load Wattage

52kw

52kw

Air Requirement

Pressure: 0.6~0.7Mpa, Flow: ≥0.37m3/min

● Drawing;

-

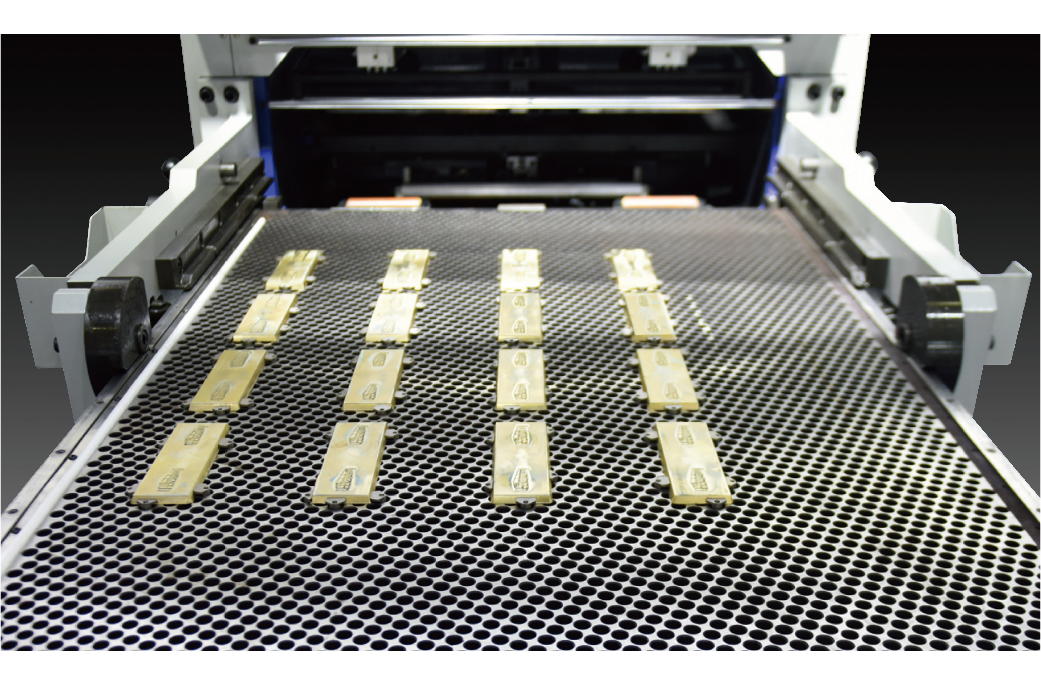

● Applications and Characters

❈ Partial Introduction:

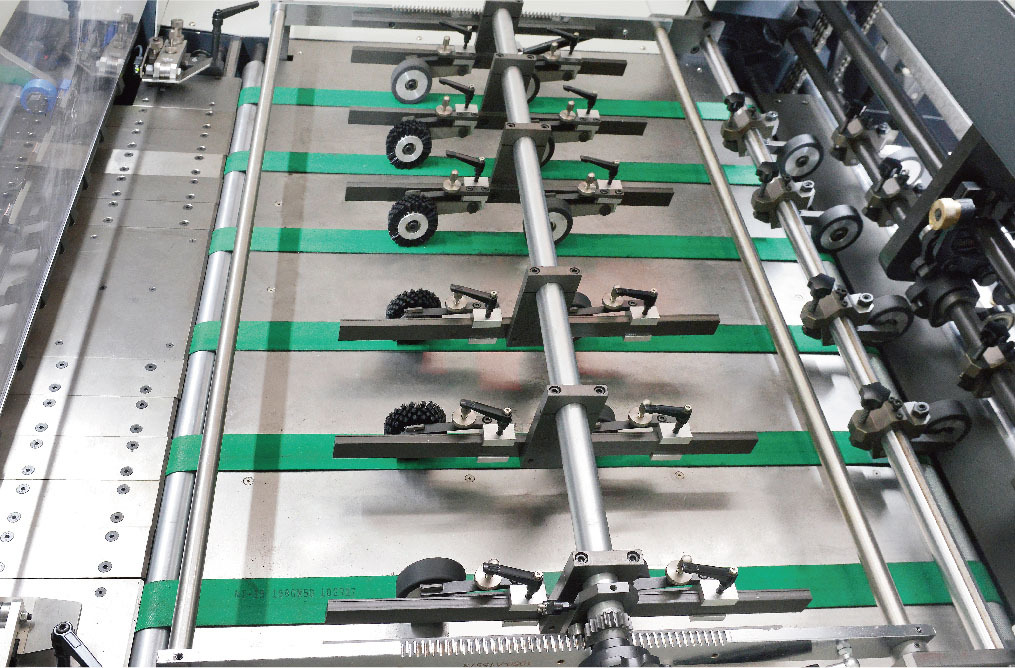

Feeder Unit:

Four pick up and four forward suck heads with angle adjustment to handle different kinds of materials.

Feeding Table:

Synchronizing device to adjust the sheetpositioning to the front lay by handduring production, Sheet hold-downdevice (guiding the sheets to the frontaws )

limine BeltDriven Device:

Taiwan high precision intermnttentsegmentation ensure high positionaprecision for long tie usage.

Paper Collecting Unit.

Automatic delivery with non - stopcurtain. This curtain moves into thedelivery to catch the arriving sheetsduring the pile exchange. two blowersfor paper collection can ensure neatcollection of thin and thick papers

Electric Appliance Unit:

Adopts electrical comp onents of worldfamous brands (OELLER /

OMRON) for better performance andin time and local after-sale-service andmaintance.

Auto lubrication System:

Hdopt concentrated auto lubricationsystem to make sure the driven partsworking better.

Paper Collecting Unit.

Automatic delivery with non - stopcurtain. This curtain moves into thedelivery to catch the arriving sheetsduring the pile exchange. two blowersfor paper collection can ensure neatcollection of thin and thick papers

Electric Appliance Unit:

Adopts electrical comp onents of worldfamous brands (OELLER /

OMRON) for better performance andin time and local after-sale-service andmaintance.

Auto lubrication System:

Hdopt concentrated auto lubricationsystem to make sure the driven partsworking better.

Paper Collecting Unit.

Automatic delivery with non - stopcurtain. This curtain moves into thedelivery to catch the arriving sheetsduring the pile exchange. two blowersfor paper collection can ensure neatcollection of thin and thick papers

❈ Configurations:

Remark: Note: This allocation sheet is for reference only, the formal allocation sheet is subject to the contract.

Standard Configuration: √; Optional: △; Not Included: ×.

Model

MHC-AT ☞ Feeding Unit

- Monolithic conveying section wall panel of ductile iron

√

- Fish scale type strong paper suction head, 4 suction and 4 feed, the suction head can adjust various paper suction Angle according to the deformation of paper

√

- Adjustable air suction tube, suction head and air distribution valve superhard alloy treatment

√

- Three feida head anti-collision devices

√

- Horizontal paper parting and blowing device

√

- The main and secondary stacking paper table does not stop alternately, feida non-stop operation, the maximum pile of paper height 1600mm

√

- Main electric left and right trimming device for paper feed stack

√

- The pre-stack device is equipped with rails so that the operator can accurately and easily load the stack into the feita

√

- Push-pull side gauge, one set for operation side and one set for transmission side. Side gauges can be adjusted between push and pull gauges to meet different paper requirements

√

- Side gauge, front gauge paper photoelectric detection

√

- Paper arrives before the gauge, slow down the function of paper

√

- Electromechanical double detector

√

- Import paper conveyor belt and stainless steel conveyor plate

√

- Pneumatic lifting device for feeding frame

√

- Single point clutch: the conveying part and the main part can be separated and combined synchronously at any time, simplifying and facilitating the operation sequence. No matter the sample, test pressure, etc., can be arbitrarily separated and closed conveyor section

√

- PLC and electronic CAM control the timing of the whole machine

√

- Germany Baker brand blowing and suction dual vacuum pump

√ ☞ Die Cutting Unit:

- Ductile iron heavy main body and left and right wall panels and upper platform, lower platform

√

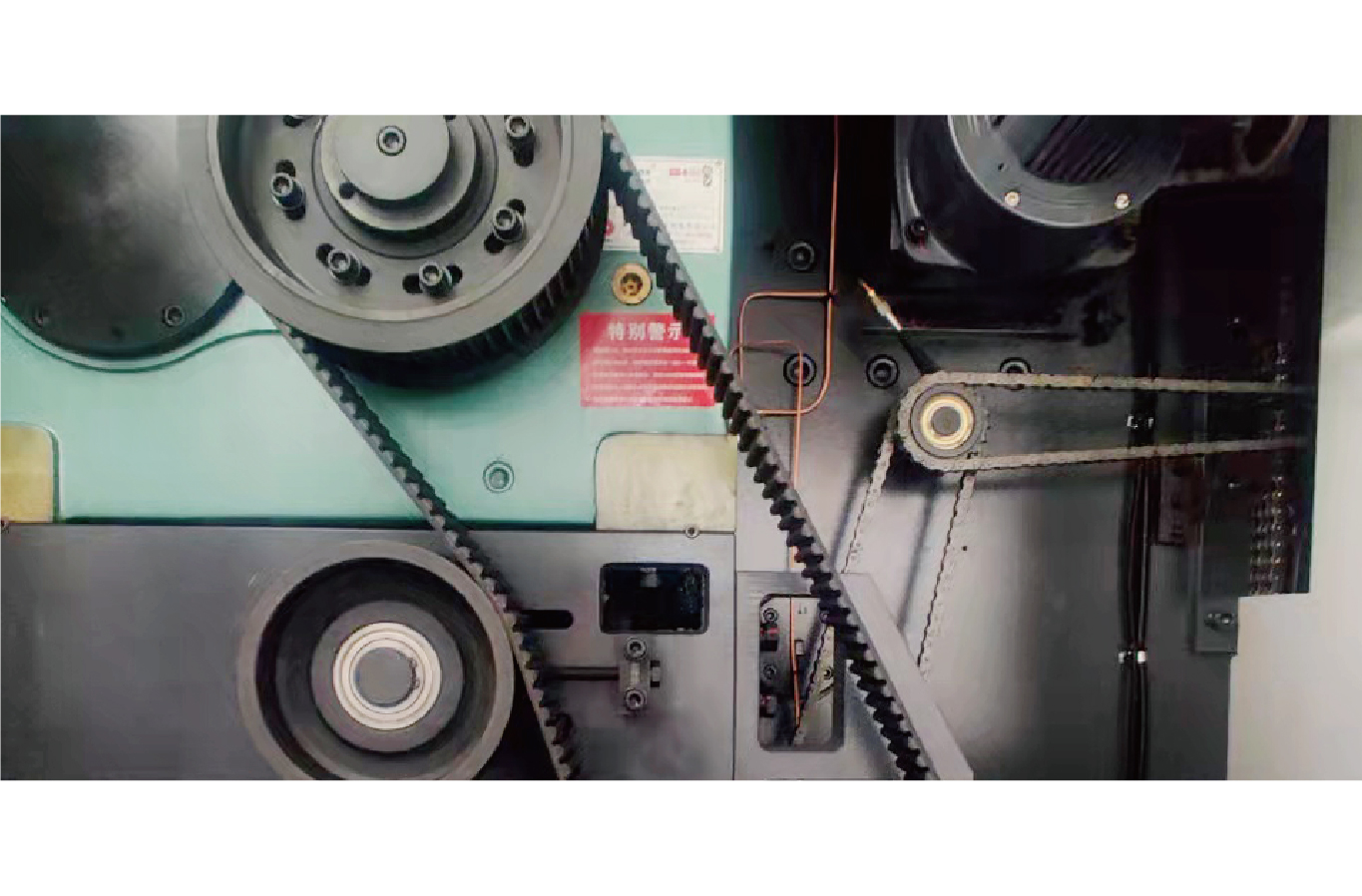

- Imported worm gear, worm with 40CR crankshaft

√

- Rotary device for die cutting bottom plate and cutter template

√

- Servo motor pressure regulating device, through THE PLC touch screen button to achieve accurate pressure control, accurate adjustment to 0.01mm

√

- Electric pressure regulating device can realize accurate pressure control through PLC touch screen keys

√

- The whole set of imported anodized aluminum alloy tooth row and positioning structure 5 groups, each tooth row adopts adjustable tooth row structure

√

- Import main drive chain

√

- Imported intermittent divider

√

- Imported synchronous belt, belt wheel drive

√

- Main drive inlet pneumatic clutch brake device

√

- Japanese SMC pressure detection device, pressure is too low alarm

√

- Die-cut plate frame adopts center line fast positioning device structure

√

- Die-cut plate frame and die-cut bottom plate are locked by Japanese SMC gas regulator, to avoid the upper plate frame lock installation is not in place, effectively avoid the loss caused by human factors operation

√

- The whole machine adopts centralized automatic oil supply system to ensure that the transmission part is not short of oil

√

- Equipped with air storage tank to ensure the stable air pressure

√ ☞ Delivery Unit

- Adjustable mechanical paper receiving brush and paper pressing mechanism to help the teeth discharge paper and stack

√

- Paper collecting and paper leveling device

√

- Photoelectric detection of the upper and lower limit switch prevents the paper from being piled too high and the paper from being rolled up

√

- Plug rod type auxiliary paper receiving frame, can realize non-stop machine paper receiving

√

- Paper receiving bidirectional auxiliary blowing, manual sampling mechanism, easy to operate

√

☞ Electrical Parts:

- Huichuan PLC control system

√

- The die-cutting part adopts 10.4 – inch touch screen

√

- All the machines adopt relays, AC contactors, air switches and buttons made by Moeller from Germany to ensure the stability and reliability of electrical parts

√

- The whole machine adopts Japanese Omron photoelectric switch, optical fiber, encoder and sensor, to ensure the accuracy and stability of electrical detection of each part of the action

√

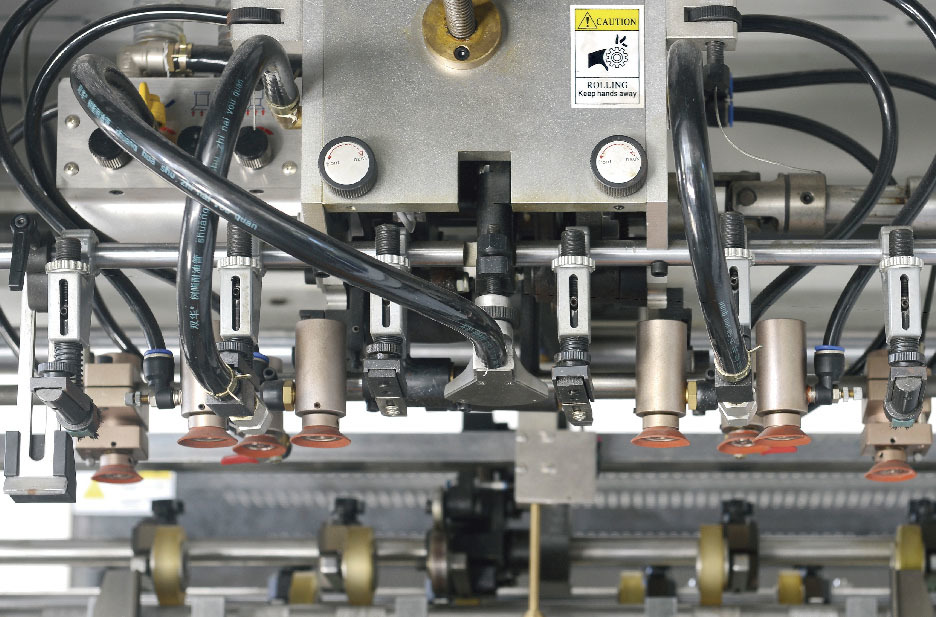

☞ Bronzing Computer Control System:

- Independent research and development of AC801 bronzing computer control system, accurate operation, fast speed, can realize high-speed intelligent skip operation of large area electrochemical aluminum foil (patent technology)

√

- Three vertical and two horizontal aluminum foil independent foil feeding system ensures smooth and accurate anodized aluminum conveying at high speed, reliable tension control and small aluminum foil stretching

√ - Three vertical bronzing foil receiving inner large surface biaxial foil receiving device (patent technology)

√ - Three vertical bronzing foil collecting outside intelligent foil collecting cabinet device

√ - The three longitudinal foil feeding frame adopts push-pull device, which is convenient to pull out the foil feeding frame from the machine to replace the aluminum foil, and the operation is simple and safe

√ - Bronzing servo adopts directly connected foil feeding shaft device with high precision

√ - Equipped with broken foil detection system to prevent the hot stamping waste caused by accidental break of anodized aluminum and improve the yield of hot stamping products

√ - Temperature zone independent control system, effectively control the heating temperature of hot stamping plate. Ensure the whole heating system temperature control more balanced and stable

√ - Vertical and horizontal bidirectional with aluminum foil separation blowing device, suitable for large area bronzing

√ - If the length of aluminum foil is less than the set parameter, the alarm will be triggered and the computer processing aluminum foil monitoring system will display the remaining and used aluminum foil length

√ - Bronzing department operating table adopts 10.4 inch touch screen

√ - Holographic anti-counterfeiting foil holder device, quick operation, safe replacement of position, convenient installation, ensure the accuracy and stability of holographic hot stamping (holographic hot stamping, optional)

△

-

Online Message

Related Products