SMC-D1100/1500/1700/1900S Digital Inkjet Printing Smart Servo Precision Double-Helix High Speed Sheet Cutter

SMC-D1100/1500/1700/1900S Digital Inkjet Printing Smart Servo Precision Double-Helix High Speed Sheet Cutter

SMC-D1100/1500/1700/1900S Digital Inkjet Printing Smart Servo Pre

- Technical Parameter

- Product Details

- Video Online Message

-

- Commodity name: SMC-D1100/1500/1700/1900S Digital Inkjet Printing Smart Servo Precision Double-Helix High Speed Sheet Cutter

SMC-D1100/1500/1700/1900S Digital Inkjet Printing Smart Servo Precision Double-Helix High Speed Sheet Cutter

● Main Specifications:

Model

SMC-D1100S

SMC-D1500S

SMC-D1700S

SMC-D1900S

Cutting Method

Dual Spiral Knife, Top Blade and Bottom Blade Rotary Cutting

Thickness of Cutting Paper

100~1000gsm

100~1000gsm

100~1000gsm

100~1000gsm

Cutting Length Range

450~1650mm

450~1650mm

450~1650mm

450~1650mm

Cutting Precision

Cutting length≤1000mm: ±0.1mm; Cutting length>1000mm: ±0.1%

Max. Cutting Meter Speed

350m/min

350m/min

350m/min

300m/min

Max. Cutting Speed

440 Cust/min

440 Cust/min

440 Cust/min

380 Cust/min

Max. Scroll Diameter

1800mm

1800mm

1800mm

1800mm

Max. Paper Cutting Width

1100mm (45”)

1500mm (59”)

1700mm (67”)

1900mm (75”)

Max. Piling Height

1600mm

1600mm

1600mm

1600mm

Air Pressure

0.8Mpa

0.8Mpa

0.8Mpa

0.8Mpa

Total Power

69KW

82KW

90KW

100KW

Voltage

3PH-50HZ-AC380V/220V

Gross Weight

18,000kgs

20,000kgs

23,000kgs

25,000kgs

Remark

The real output depends on the material, and the weight of the paper, and right operate process

● Cutting Speed:

Model

SM-D1100/1500/1700

SM-D1900

Cutting Length (mm)

Speed (m/min)

Speed (Cust/min)

Speed (m/min)

Speed (Cust/min)

450

125

275

100

210

500

160

315

110

220

550

190

350

135

240

600

210

350

155

260

650

250

380

190

290

700

290

410

230

320

750

330

440

290

385

800

330

410

300

380

850

330

385

300

355

900

330

365

300

345

950

330

350

300

320

1000

330

330

300

300

1050

320

300

300

285

1100

310

280

290

265

1150

300

265

285

250

1200

300

250

280

235

1250

300

240

270

220

1300

300

230

260

210

1350

300

215

260

195

1400

300

210

260

190

1450

300

200

260

180

1500

300

195

260

175

1550

300

190

260

168

1600

300

188

250

160

1650

300

185

250

155

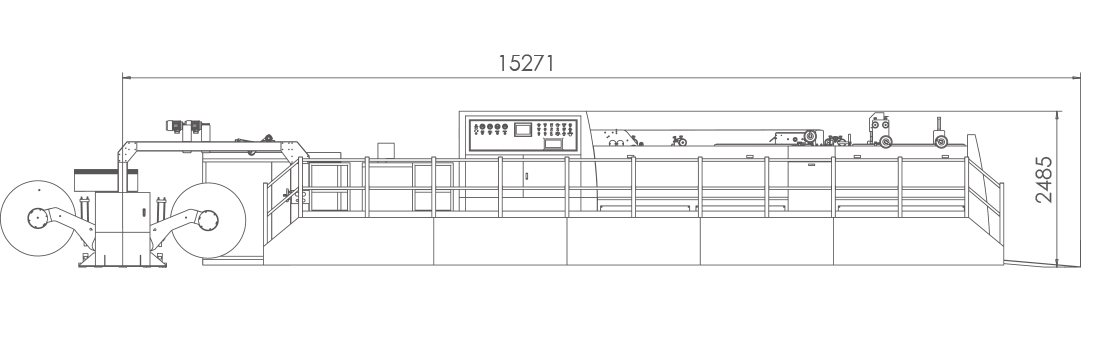

● Layout:

-

● Applications and Characters:

Based on the technology of SM-D series Servo precision Double-helix High Speed Sheet Cutter Machine, SMC-D series equipped with more intelligent function and better technological innovation.

- Auto positioning slitting system.

- Paper pre-press device.

- 3 times delivery device (no impression line).

- Collecting board pneumatic lifting device.

The SMC-D series Smart Servo Precision High Speed Sheet Cutter Machine (Synchro- fly twin knife) can efficiently complete slitting, rip cutting and trimming of products, as well as maintaining the highest precision and product quality.

The SMC-D series Sheet Cutter Machines are well equipped and almost can adapt to all die cutting requirements of products. Paper after cutting is smooth without any powder, can be put on printing machine immediately.

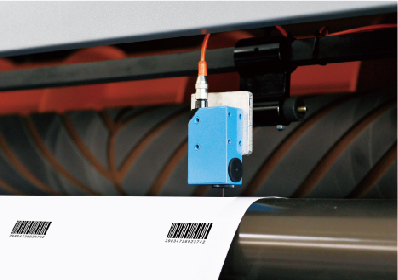

Digital ink-jet printing is a printing type of non-contact, non pressure, non plate printing. All digital information can be printed by inputting the digital ink-jet printer through the interface. The traditional ink-jet printing is printing first, then ink-jet printing, which is low efficiency and large loss in paper. At present, the Digital Ink-jet Double-helix High Speed Sheet Cutter Machine developed by our company is to print QR code, bar code and digital pattern on the jumbo roll first through digital ink-jet, then cut the jumbo roll into single sheets, realizing intelligent and efficient detection, enabling digital ink-jet printing and slitting to be completed at one time, greatly reducing paper loss.

- Adopt nodular cast iron-QT500-7, original paper frame clamp arms casting by special technology process, thus featuring by high strength, never deformation and ensure the safety of original paper frame clamp arms .

- Adopt nodular cast iron-QT600-7, the mainframe wallboard and cutter base has precision manufacturing and high strength , thus will never-deformed .

- The machine uses NSK bearings.

- The machine uses original parts imported from Germany Siemens, Japanese OMRON and Germany Moeller, etc

- Die cutting accuracy reach to ± 0.1mm, the highest speed reaches 440 sheet/min.

- The back cutter is adopt Germany Ni-Cr-Mo metal Tungsten steel material, with high precision and will never- deforms; the knife edge is easy to adjust and calibrate.

- Equipped with the company first-developed anti-curve automatic regulation device, ensure fast and smooth when they adjust of anti-curved paper.

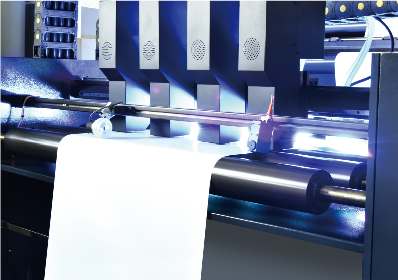

- Paper feeding part adopts pre-pressing device, to ensure that the paper is not wrinkled.

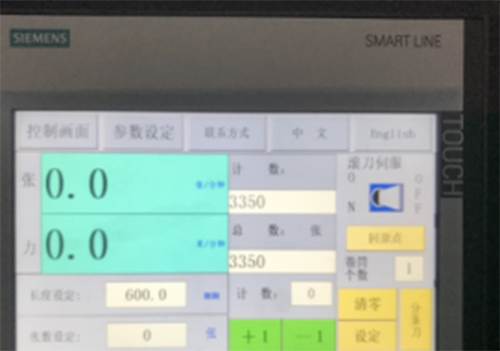

- Equip with touch-screen operation interface in both Chinese and English.

- Adopt Japanese SMC auto tension system and pneumatic components to ensure every pneumatic action performs accurately.

❈ Partial Introduction:

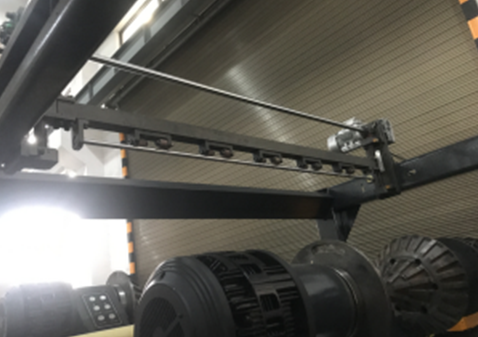

Reel Stand, Paper Feeding:

- Max. paper roll diameter: 1800mm

- Max. paper-cutting width: 1100/1500/1700/1900mm

- Min. paper-cutting width : 500mm(20″)

- Paper cylinder diameter: 3″, 6″ or 12″

- Hydraulic drive:

-

Tension control system: Pneumatic tension control and swing roll to adjust the pressure arm rise or fall, to control the strength of brake

5.1 Open/close and forward/backward movement of paper roll clamp arms is driven by oil hydraulic cylinder

5.2 Lifting of paper roll clamp arms is driven by oil hydraulic cylinder

- Pneumatic brake brakes, automatic brakes

- Paper guide roll and relevant brackets

Side Folding Device:

- Type: Adopt motor drive and high-speed adjustment

-

Anti-curve device: Anti-curve guide roll adopts patented design and efficient anti-curve treatment

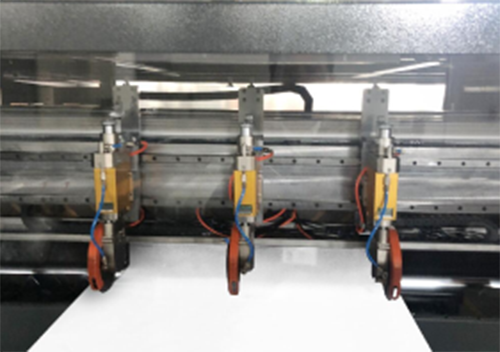

Register Unit:

- Adopt electric control and inching mode, to make the pressing roll moving vertically, ensure proper positioning of feeding paper, and reduce the phenomenon of paper creping.

Transfer Section:

- Type: Adjustable trimmed splitting knife and suction duct fan and air hose on both sides of waste paper edge.

- Upper knife: Adjustable rising and falling, switch type slitting knife, and paper cutting clearance can be adjusted manually.

- Lower knife: Knife shaft fixed the upper and lower position , and paper cutting clearance can be adjusted manually.

- Fan: 1.5KW motor drive.

- Y type waste paper edge collection pipe and fixed frame.

Cutting Part:

- Twin knife: Adopt cast iron integrated forming casting, and combine with precision finishing, to have better stability.

- Drive roll: Roller 's surface adopts the expansion texture design and controls the pressurized clip paper of roller through the cylinder.

- Back cutting knife: Made of special alloy steel through precision finishing, thus having long service life; the blade is easy to adjust and calibrate.

- Safety cover: The machine stops automatically when the safety cover is open, so as to guarantee safety.

Man-machine Interface:

- Electrical control system is easy to operate.

- The cutting length, quantity and number of finished products can input directly.

- The actual cutting length and cutting quantity can be displayed in real time.

Static Elimination Equipment:

- Type: Plasma rod type, to eliminate the static electricity on paper.

- Main machine: Efficient static electricity.

- Static elimination rod: Effective discharge range 1700mm.

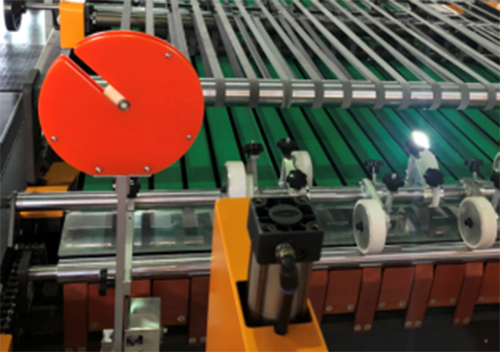

Paper Conveying Equipment:

- Type: Horizontal multi-stage differential feeding, to produce separation count and paper stacking effect.

- First conveyor section: Quickly separate papers after cutting.

- Second conveyor section: Can be controlled independently or jointly, and adjust the paper to feed out in imbrication type.

- Third conveyor section: speed reduce, prevent paper from impression.

- Paper-out conveyor section: Refined paper separator, can be adjusted by the matched with paper width. pressurized feeding wheel to increase the stability of paper and avoid inclination of paper.

Automatic Paper Alignment and Collection Equipment:

- Type: Hydraulic lifting and stacking collection paper table, descend automatically when the paper stacks to a certain height.

- Maximum effective paper stacking height: 1600mm (including pallet)

- Paper collection size: Width = 1100/1500/1700/1900mm, Length = 1600mm.

- Paper alignment equipment:

- Electric type positive paper alignment mechanism.

- Electric type paper alignment mechanism on both sides.

- Turnover type rear retaining board mechanism.

- Hand-operated and both sides moveable of paper alignment mechanism.

Automatic Counting Label Insert Equipment:

- Type: Accurate counting transverse inserting.

- Function:

- Set the input the number of label in the soft-touch type computer interface, to insert the label according to the set value.

- Sheet replenish function of non-conforming products.

Auto Roll Curtain Delivery Equipment:

- Type: auto curtain delivery

- Function:

- Once one pallet is full, no need to stop machine to take it out. Operator can start auto curtain function help to delivery during exchange pallets.

- Save paper which caused when stop machine.

- Higher efficiency

-

Online Message

Related Products