VFGH-1250/1450/1650/1850/2050E High Speed Automatic Lock Bottom Corrugated Folder Gluer Machine

VFGH-1250/1450/1650/1850/2050E High Speed Automatic Lock Bottom Corrugated Folder Gluer Machine

VFGH-1250/1450/1650/1850/2050E High Speed Automatic Lock Bottom C

- Technical Parameter

- Product Details

- Video Online Message

-

- Commodity name: VFGH-1250/1450/1650/1850/2050E High Speed Automatic Lock Bottom Corrugated Folder Gluer Machine

VFGH-1250/1450/1650/1850/2050E High Speed Automatic Lock Bottom Corrugated Folder Gluer Machine

● Main Specifications:

Name

VFGH-1250/1450/1650/1850/2050E

High Speed Automatic Lock Bottom Corrugated Folder Gluer Machine

Max. Linear Speed

280 m/min

Suitable Paper Quality

200~800 g/m2 Cardboard;

A, B, C, E, F, N, AB Flute, 3 Layer Corrugated Paperboard

Way of Folding in Reverse

Fold 2 and fold 4 are 180°

Feeding Way

Automatically and Continuously Feeding

Adhesive

Water Base Cold Glue

Electrical Power

3PH-380V-50Hz-20kw

Weight

8000/8500/9000/9500/10000 Kg

Dimension

15800×2000/2200/2400/2600/2800×1700 mm

Belt Width of Folding Unit

50-35-50mm or 70-50-70mm

● Main Technical Parameter:

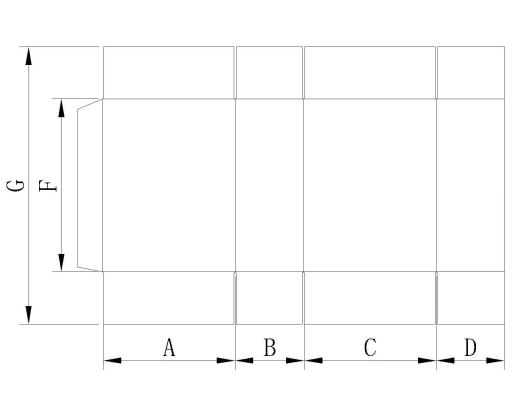

☞ Flat Box Type and Size: (mm)

Model

1250E

1450E

1650E

1850E

2050E

A+B+C+D

200-1200

200-1400

200-1600

280-1800

280-2000

C+D Min

100

100

100

140

140

D Min

25

25

25

25

25

F Min

100

100

100

100

100

G

150-800

150-800

150-800

150-800

150-800

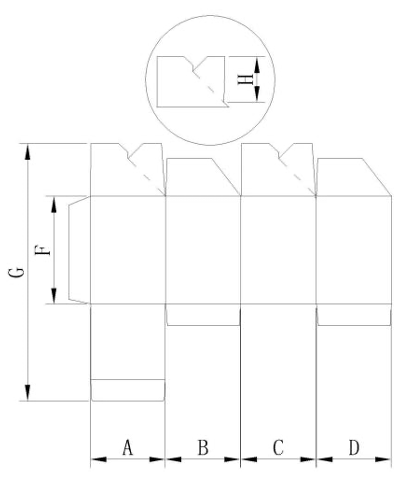

☞ Lock Bottom Box Type and Size: (mm)

Model

1250E

1450E

1650E

1850E

2050E

A+B+C+D

250-1150

250-1350

250-1550

380-1750

380-1950

C+D Min

125

125

125

190

190

D Min

25

25

25

25

25

F Min

100

100

100

100

100

G

150-800

150-800

150-800

150-800

150-800

H Min

30

30

30

30

30

NOTE: The machine speed should be based on the actual sample box sized be based on the actual sample box size

-

● Applications and Characters:

VFGH-1250/1450/1650/1850/2050E High Speed Automatic Lock Bottom Corrugated Folder Gluer Machine, it adapts electrical plate adjustment, PLC and imported electronic components, feeding section adopts independent electrical control, operation on rail with stable performance and easy to control and operate. This machine is specialized for cardboard and corrugated cartons, its correction function make corrugated cartons perfectly meeting the requirements of packing industry. (We can customize for other sizes.)

It is specially for making boxes from flute A, B, C, E, F, N, AB flute like wine box, carton box, average speed 8000pcs/hr depends on different box size, this series widely applied to wine factory carton factory and the other post press finishing, this series save labor force by four fifths ,also reduce the glue by two thirds, it’s preferred product for post-press finishing.

❈ Featuers

Feeding:

- Adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding.

- Continuously Variable Speeder to ensure feeding internal and stable transmission.

- One-touch Pneumatic knife, easy for the adjustment of feeding belts

Alignment

- Alignment section which automatically corrects thebox after it is ejected from the paper feed section.

Auto Indentation:

- Secondary indentation process for 2 and 4 lines of flatcortugated box.

Bottom Lock.

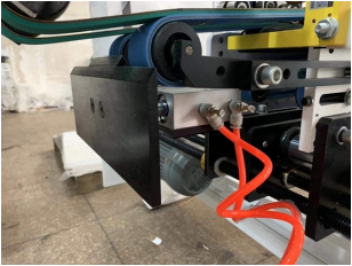

- 3-board tracking structure, upper glue can makebottom-locked box automatic gluing and forming, canbe used for the special-shaped cartons. The entirebottom-lock part is installed in a reversible bracketsubstantially reduce the swap adjustment time ofbottom-fold box and the other types of box.

- Bottom-folding speed is 50~200pcs per min, stableand reliable.

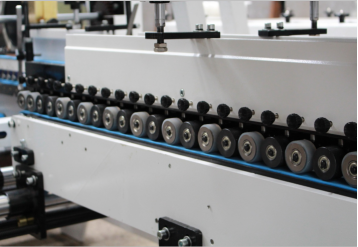

Folding:

- Lengthened folding to avoid the unevenness while therapid forming of catons and make it come to perfection

Ful1 Pressing

- 2-board structure.

- Two modes for pressing belt speeding

- Auto: set distance between boxes, pressing beltspeed is the samme as the machine, belt removeswhile sensor detect it.

- Manual: pressing belt conveys in a fixed speedand machine speed will not put any effect on it.3With counting device to count the finished boxes tomatch with boxes.

- regulating, easy to count and pack

Transmission:

- Equipped with feeding paper inspection device.

- Equipped with impacting device to press the paper after accounting and make it easy to pack paper.

Flapping Device:

- Using new Pneumatic Flapping Device instead of oldMotorized Flapping Device, it is better for avoidingpaper blocking to damage motors and electricalcomponents. It is only used for Flat Box making sohat it can reduce the fish tail and forfex error ofcaiton box.

Auto Motor Adiust:

- The machine adapts electrical plate adjustment, fast to adjust

PLC Touch Screen:

- The machine adapts touch screen adjustment, fast toadjust.

CCTVMonitors

- The machine adapts CCTV monitors which could seethe production process.

The Grinding Part:

- More effective treatment of paper surface UV, thecarton adhesive more stronger.

Optional: KO Brand Spraving System: Water Base ColdGlue System.

- For irregular box

- Need Extra Spraying System.

- Equipped with three guns, convenient in theproduction various special box, gluing quickly andaccurately sizing(Options: customized on user order)

Optional: Box Collection Device:

- The machine adapts CCTV monitors which could seethe production process. The machine reduces laborintensity, saves manpower, improves the working efficiency of the folder gluer machine, and can make theperformance of the folder gluer machine fully play

Optional: PlasmaSystem

- Through surface coating treatment, to strengthen the adherence and make catons easier to be glued.

Optional: Box Bundling Machine.

- The machine reduces labor intensity, saves manpower.improves the working efficiency of the folder gluermachine, and can make the performance of the foldeigluer machine fully play.

● Carton Box Samples:

-

Online Message

Related Products